TAILORED COLD STORAGE DESIGN FOR AGRICULTURAL & SEAFOOD PRODUCTS IN VIETNAM

One Product, One Precision-Cooled Solution

In the world of cold storage, one-size-fits-all is a costly myth. You cannot preserve Hoa Loc mangoes the same way you freeze black tiger shrimp. Each agricultural or seafood product requires its own temperature curve, humidity level, cooling dynamics, and air distribution logic.

At VMTech, we believe:

“Every product speaks its own refrigeration language — our job is to listen and design accordingly.”

1. Agricultural vs. Seafood Cold Chain – Different Demands, Distinct Solutions

Agricultural Produce – Gentle Cooling, Stable Conditions

- Ideal storage temperature: 8°C to 15°C, depending on the crop (mangoes, durians, dragon fruits, root vegetables, etc.)

- Humidity levels: 85%–95% to maintain freshness and prevent wilting

- Smooth, indirect airflow to prevent moisture loss

- No exposure to direct sunlight; humidity and air temperature should remain stable and evenly distributed

Seafood – Fast Freezing, Deep Preservation

- Quick freezing required at -18°C to -40°C, with storage at -18°C to -25°C

- Critical to maintain consistent deep freeze, avoiding thaw-and-refreeze cycles

- Hygienic construction with 304 stainless steel finishes to withstand corrosion

- Airflow must cover every corner to eliminate thermal dead zones

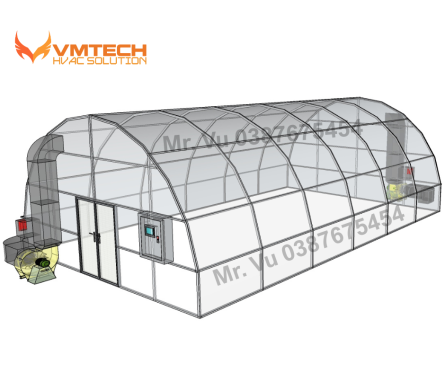

2. Precision Engineering for Cold Room Performance

Panel Insulation Tailored to Product Type

- For agriculture: PU panels 75–100mm thick – moisture-retaining and energy-efficient

- For seafood: PU panels 100–150mm thick, finished in stainless steel for anti-corrosion

Accurate Cooling Load Design

- Produce requires slower, stable cooling using moderate compressor systems

- Seafood demands high-capacity systems, often including dedicated blast freezers for rapid freezing

Smart Control Systems

- Automated temperature & humidity adjustments

- Real-time deviation alerts

- Remote monitoring via mobile app or web dashboard

Optimized Airflow & Door Design

- Circular, non-direct airflow avoids dehydration

- Thermal-insulated doors, air curtains, and PVC strip curtains minimize cold air loss during operation

3. Why Custom Cold Storage Matters

✔️ Preserves integrity, color, nutrients, and texture of products

✔️ Extends shelf life, ensuring flexibility in sales and export timelines

✔️ Reduces energy consumption through right-sized design

✔️ Enhances brand trust, especially for export-oriented businesses

✔️ Meets international hygiene and quality standards

4. VMTech – Your Trusted Partner in Cold Storage Excellence

With operations rooted in Vietnam’s agricultural and seafood heartlands — from Nha Trang, Khánh Hòa, Phú Yên, Lâm Đồng, Ninh Thuận to HCMC and Đồng Nai — VMTech delivers world-class cold room systems customized to your products and production scale.

- Bespoke designs matched to product requirements

- Eco-friendly, energy-optimized solutions

- Fully integrated smart monitoring

- Turnkey delivery: Design → Installation → Commissioning

5. From Farm & Sea to Global Markets

In the cold chain, precision is profit.

Whether you're preserving tropical fruits or frozen seafood, your cold room is not just a storage unit — it's a strategic asset.

Choose VMTech to ensure your products arrive in perfect condition, anywhere in the world.

📞 Hotline: 0387 675 454

🌐 Website: https://vmtech.vn

📱 Facebook: Vmtech – HVAC Solution